Flex Pipes

Discover the most extensive range of flex pipes on the market, crafted to meet the diverse demands of modern engine and exhaust systems. Available in both traditional and elliptical cross-sections, our flex pipes are engineered for durability, performance, and customization.

Read More

Clamps

Our clamps are engineered to deliver unmatched performance and reliability in exhaust systems, offering a wide variety of options with OE analogs to meet diverse customer needs.

Read More

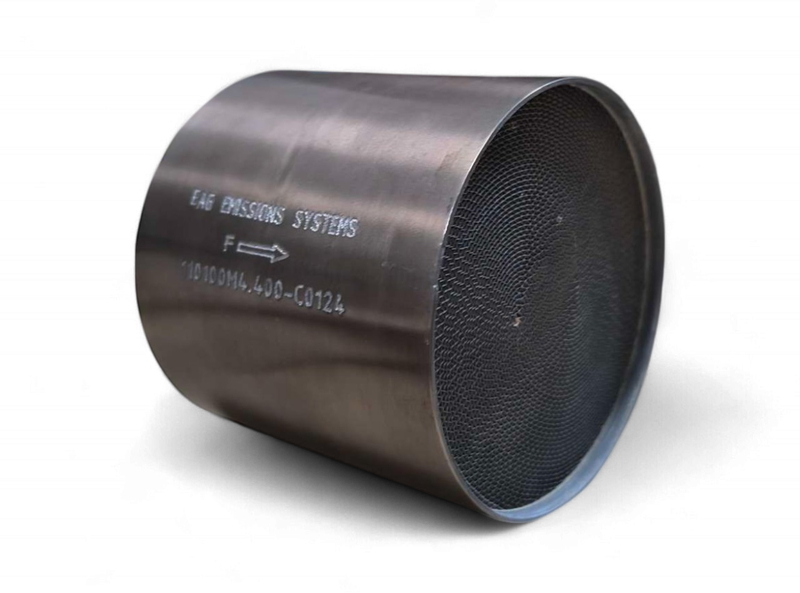

Exhaust Catalyst Cores

Our exhaust catalyst cores represent the pinnacle of innovation and precision engineering in exhaust system components, offering solutions that meet EURO 4, EURO 5, and EURO 6 emission standards.

Read More

Metal Hoses

Our metal hoses are designed to deliver durability and flexibility across a wide range of industrial and automotive applications, with specialized options for trucks, forklifts, and air-heaters.

Read More

Repair Parts & Accessories

Our repair parts and accessories are designed to simplify exhaust system maintenance, offering reliable solutions such as muffler brackets, O2 sensor adapters, and more.

Read More

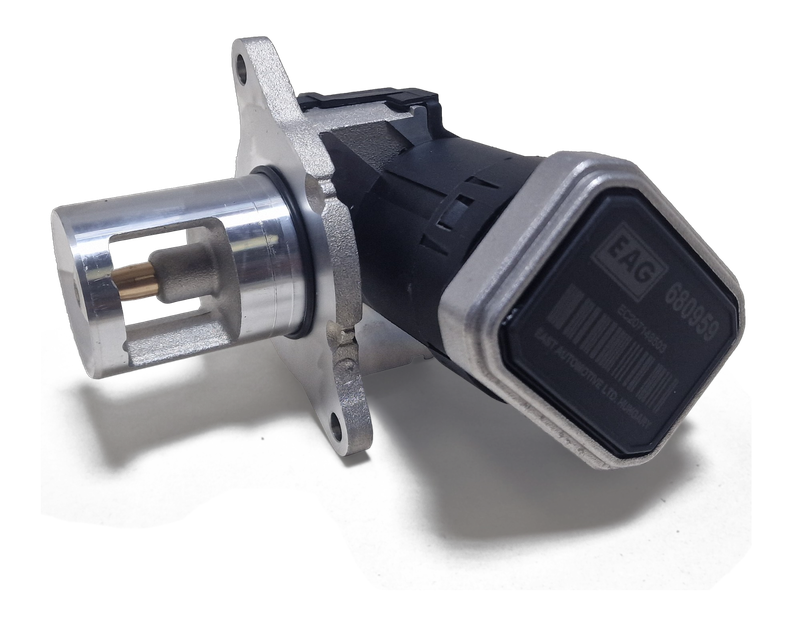

EGR & Intake Systems

Our EGR & Intake Systems are designed to optimize engine performance and meet modern emission standards, ensuring efficient and reliable operation. Built with precision and using high-quality materials, these components are ideal for various engine configurations.

Read More