Scope of Application

The exhaust flex pipe is designed to compensate for movements and mechanical vibrations of the engine.

It is universally applicable in exhaust systems.

Manufactured Products

- Flex pipes of all required diameters, available in traditional and elliptical cross-sections.

- Optional heat shielding (corrugated metal hose) or heat pipe to streamline airflow within the exhaust system.

- Mounting hardware (provided according to customer specifications).

Technical Specifications

- Engine and exhaust system vibration compensation.

- Absorption of engine vibrations.

- Customizable vibration-absorbing properties.

- Compact design.

- Hermetic sealing.

- Resistance to extreme temperatures.

- Corrosion resistance due to the use of suitable materials.

- Custom production available for specific installation conditions.

Types of Exhaust Flex Pipes

Innerbraid

The most common type of vibration compensator, Innerbraid, is used in the vast majority of vehicles.

Characteristics:

|

|

|

| End cap | Outer layer | Inner layer |

- Bellow – stainless steel AISI 201

- Braid – stainless steel AISI 201

- End cap – stainless steel AISI 409

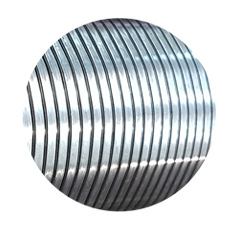

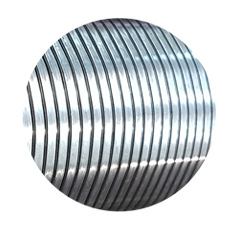

Interlock Exhaust Flex Pipe

The design of the Interlock vibration compensator includes the use of a high-quality, corrosion-resistant steel hose, enabling the structure to withstand extreme temperature fluctuations and significantly extend the part’s service life.

|

|

|

| Specially designed end caps | Outer layer | Inner layer |

Characteristics:

- Bellow – stainless steel AISI 304

- Interlock hose – stainless steel AISI 304

- Braid – stainless steel AISI 304

- End cap – stainless steel AISI 409

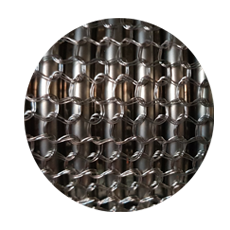

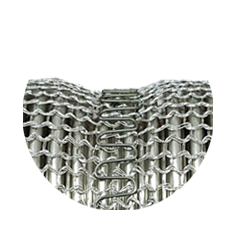

Wire meshed / Soft meshed

One of the most efficient types of flex pipes in the EAG lineup, offering enhanced flexibility and reinforced with a metal hose. This type of flex pipe is supplied to assembly lines of most modern automobile manufacturers

|

|

|

| Specially designed end caps | Outer layer | Inner layer |

Characteristics:

- Bellow – stainless steel AISI 304

- Interlock hose – stainless steel AISI 304

- Braid – stainless steel AISI 304

- End cap – stainless steel AISI 409 / 304

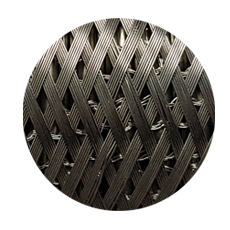

Wire meshed and braided / Reinforced Soft Meshed

A unique type of flex pipe by EAG, with no analog in the aftermarket, combines the positive qualities of the standard Interlock flex pipe with Wire Meshed technology. The Wire Meshed and Braided flex pipe is reinforced with an additional outer braid, offering enhanced noise reduction and improved heat resistance. This makes it exceptionally suited for extreme operating conditions and high-load applications.

|

|

|

| Specially designed end cap | Outer layer | Inner layer |

Characteristics:

- Bellow – stainless steel AISI 304

- Interlock hose – stainless steel AISI 304

- Braid – stainless steel AISI 304

- End cap – stainless steel AISI 409 / 304

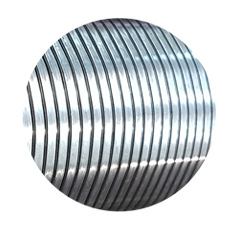

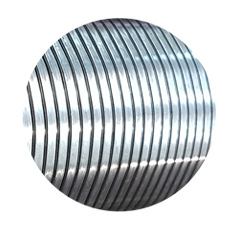

Dumbbell Meshed – High-Strength Exhaust Flex Pipe

The Dumbbell Meshed flex pipe is designed for enhanced durability. To achieve high-strength characteristics, the bellows element features alternating crest heights, while the outer braid is angled precisely to specified degrees. Additionally, a spring element is incorporated to ensure closer contact between the bellows and the outer braid. This design allows for more effective absorption of excess vibrations from the vehicle’s exhaust system, enabling even distribution of shocks and vibrations across the entire bellows. As a result, the flex pipe’s durability is significantly increased.

|

|

|

| Specially designed end caps | Outer layer | Inner layer |

Characteristics:

- Bellow – stainless steel AISI 304

- Interlock hose – stainless steel AISI 304

- Braid – stainless steel AISI 304

- End cap – stainless steel AISI 304